|

Sinker MoldsMake Personalised Molds

|

When you pour the first sinkers you'll find that the moist potato will sputter and sizzle. But after you pour two or three sinkers it will dry out and then you'll have no more difficulty in this regard.

Naturally, the potato mold doesn't last very long and after a while it dries up and shrivels too much to be of any use. However, a potato sinker mold is inexpensive and so simple that you can make another in a matter of minutes.

Another inexpensive and simple sinker mold to make is to use a chunk of hard wood and drill and carve out a sinker cavity. Here, too, the mold is one piece and you are limited to the types of sinkers made with the potato mold.

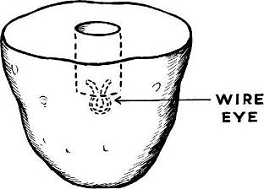

You can make a good dipsey sinker mold from a wood block by drilling a cavity on one end with different-size drills. First start with a large-size drill and drill only a short distance below the surface.

Then use a slightly smaller drill and go a bit deeper, then a still smaller one to reach the full depth you want. After which you use a knife and gouge the ridges from the cavity.

Wood carving tools are also good for this work. Cut a small slot in the far end of the cavity to take a wire eye, and the sinker mold is ready for use.

Such a mold is shown above. It will last for quite a while before the hot metal burns it out too much. If you have a drill press or an electric drill and other metal-working tools you can make such a one-piece sinker mold from a piece of metal.

Brass, copper, or bronze are easiest to drill and cut, but you can also use iron and drill out a sinker cavity similar to the wooden mold described above. Once made, such a mold will last forever and will make thousands of sinkers.

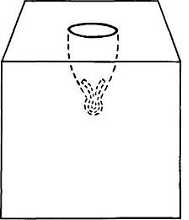

When making sinker molds for other types of sinkers such as the ball or bank, you make a two-piece mold similar to the types made for jig molds . These can be from plaster of Paris or water putty if you want temporary, inexpensive molds.

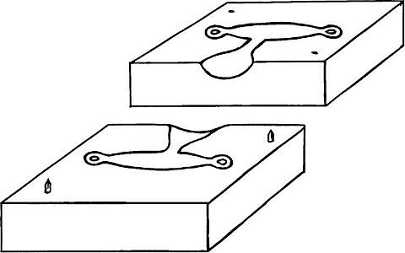

In making such a two-piece sinker mold, you can have two cavities and pour two sinkers at a time instead of just one. See illustration below. So when you get a cardboard box or make a wooden frame for such a mold make sure it is big enough.

As noted, the procedures in making a plaster of Paris or water putty mold are similar to those described for jig molds . However, instead of using the actual sinker for a pattern you should carve such a sinker pattern from soft wood, wax, or soap.

The lead sinker itself cannot be used because it is too heavy and will sink into the wet plaster when it should float in the stuff.

Remember that in making a two-piece sinker mold the pattern should be pushed only halfway into the wet plaster. When the first pouring hardens you grease the top and the part of the pattern still visible, and pour the other half.

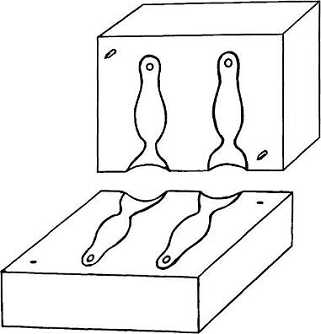

You can also make two-piece plaster of Paris molds to pour various types of trolling weights, as shown in the illustration below. These trolling weights are usually cylindrical or keel shaped and have eyes on each end, to which the fishing line or leaders are attached.

When making a two-piece sinker mold to pour such trolling weights, you must cut out grooves at both ends of the cavity to take such wire eyes or barrel swivels on each end. Such a mold for making trolling sinkers is shown here.

The potato, wood, and plaster sinker molds described above will usually last long enough to make a couple of dozen or so sinkers. If you want to make a permanent mold which will last indefinitely, make a plaster mold of the type you want and take it to a foundry.

If you have any special designs you want made this is certainly the best procedure. However, if you want a permanent sinker mold for a standard-type sinker you can buy a cast iron or aluminum mold in almost any fishing tackle store.

They can also be ordered by mail from some of the supply houses. Such permanent molds are inexpensive and will last for a long time.

When using metal sinker molds, a few words of advice are in order. Make sure your mold is warm and dry, and heat the lead well above the melting point before pouring it into the mold.

Otherwise, the molten metal will solidify and form imperfect sinkers before it has a chance to reach all parts of the mold. After a while you'll be able to tell what the best pouring temperature is by watching the color of the molten metal.

When pouring sinkers and weights, remember that it's a good idea to scoop the scum and dirt off the top of the molten lead at regular intervals so that it pours with no trouble.

|

| Freshwater Fishing | Bass Fishing | Saltwater Fishing | | Fishing Spoons | Fishing Spinners | Fishing Jigs | | Sinkers | Making Fishing Leaders | Hand Tools | | Link To Us | Contact Us | Preferred Partners | About This Site | | Site Map | |

| Back to Top of Sinker Molds |

Make-Your-Own-Fishing-Lures.com

© 2004 Make-Your-Own-Fishing-Lures.com. All Rights Reserved.